Home » Environmental Monitoring & Sampling » Remediation with direct push tooling

Environmental Monitoring & Sampling

Direct-Push has re-defined how contaminated sites are assessed

We are experts at executing environmental sampling programs at complex sites. CDS has a broad base of experience, at hundreds of sites across western Canada, using direct-push tools, techniques and equipment.

Injecting remediation compounds to destroy or remove contaminants “In-situ” is a technology widely accepted by industry and regulators across North America.

We have experience developing, supporting and executing remediation programs that specifi cally target both DNAPL and LNAPL type compounds in challenging conditions including cold weather (-10°C). We have the experience and equipment to address the unique challenges posed by compounds that sink (industrial solvents and others) and those that fl oat (refi ned petroleum hydrocarbons and others):

In-situ chemical oxidation of chlorinated solvents using MAKO injection tooling

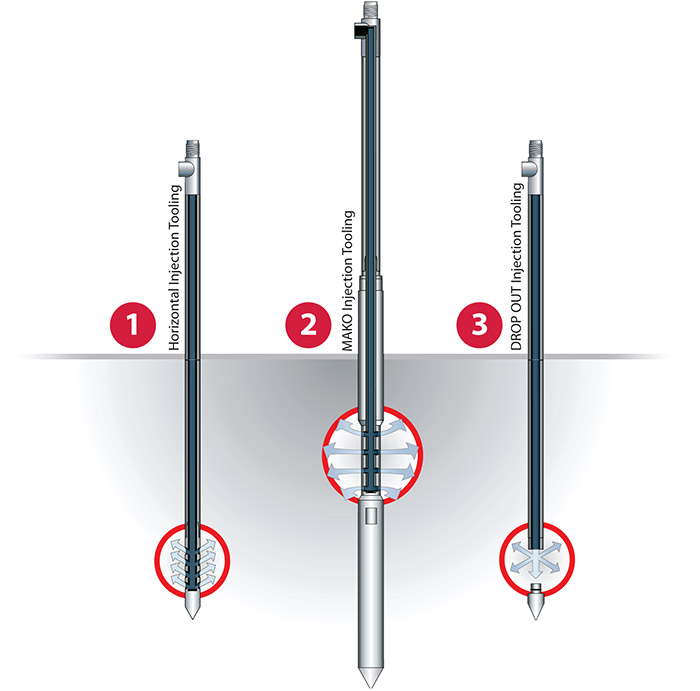

Horizontal Injection Tool for tight lithologies. It may be used while pushing or pulling the tool string.

Mako Injection Tool for coarse soils and open boreholes

Expendable Tip injection tooling for bottom-up injection or grouting. Inject while pulling the tooling from total depth to surface in a loose or coarse lithology. The tip remains at the bottom of the hole.